The ŘETĚZY VAMBERK company offers a full range of roller chains of all dimensions (pursuant to the DIN, ISO, ČSN, ANSI and GOST standards) and versions (zinc plating version, nickel plating version and stainless steel version). Exact manufacturing on modern equipment, top-quality materials applied and the correct heat treatment guarantee high resistance to wear and dynamic load. We shall gladly meet any customer requirements for design, dimensions, raw material, lubrication, heat and surface treatment of the chains and sprockets. Therefore, you can find a number of roller chains to your specific requirements within our product range - referred to as the roller chains to works standard.

Roller chain range

Roller chains (A series) according to DIN 8188 (American) and (B series) according to DIN 8187 (European), ISO - R 606, CSN 02 3311, GOST 109947-64

Roller chains with straight plates (A series) according to DIN 8188 (American) and (B series) according to DIN 8187 (European), ISO - R 606, CSN 02 3311, GOST 109947-64

Self-lubricating roller chains (A series) ANSI standard (SL) and ANSI HEAVY (SLR), self-lubricating SLR (B series) and self-lubricating with MF seal (A and B series chains)

Roller chains (A series) ANSI HEAVY (SLR), roller chains (A series) ANSI SUPER and ANSI SUPER HEAVY

Double pitch roller chains (A and B series) from 25.4 mm (1,000 inch) to 101.6 mm (4,000 inch)

Side bow roller chains are broadly used in the food industry, packaging industry and textile industry.

Roller chains with attachments in a wide range and in stock. On request, any shape, size and arrangement of attachments.

Roller chains with toothed plates are manufactured mainly for the wood and paper industry. Any shape and size on request.

Roller chains with extended pins. On request, we can produce any shape, size and pin arrangement.

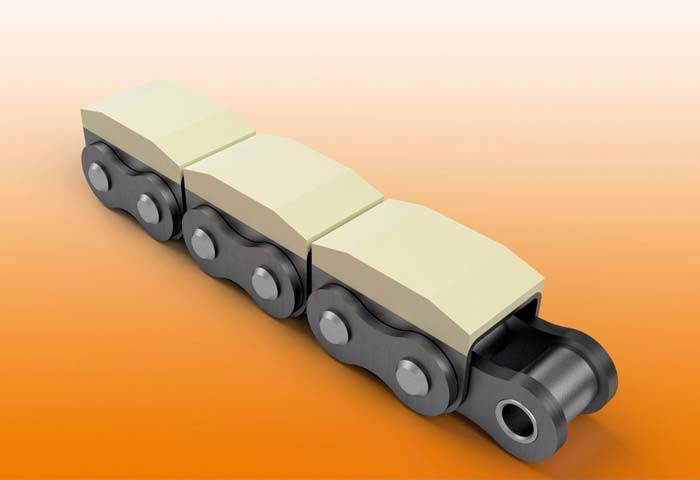

Roller chains with rubber blocks and U type attachments. On request we can produce any shape, size and arrangement of rubber blocks and links with U type attachments.

A wide range of accumulation chains in different performance classes and sizes. Rollers hardened, stainless steel, nickel plated or plastic.

Roller chains with increased wear resistance. This WAX lubrication method extends the maintenance interval of your chains by up to 300%.

Special roller chains represent one of the largest part of our production. Design, dimensions, materials, lubrication and processing according to customer requirements.

We are the exclusive representative for the Czech and Slovak Republics of the Japanese manufacturer of top quality and high performance roller chains Sugiyama.

We offer chains for most motorcycle types, from the smallest mopeds and small to powerful high volume motorcycles.